Services

Our goal is to facilitate “best in class” product design within high-profile global companies. We specialize in working with our customers to design award-winning products, but we don’t stop there. We are also prototype builders, product developers, and master pattern drafters. We are a process driven design studio, and have evolved a design paradigm in which we combine our disciplines into a powerful design process.

We call our process “Vertical Design”

Vertical design is the connection between design and prototype development. By linking design and development we are able to refine the development process. Many of our “eureka” moments occur during the evolution of the prototype development phase. Our studio is equipped with state-of-the-art machinery which allows us to quickly create working examples from design concepts. Thus we are able to rapidly test ideas and perfect designs. Our end products accurately reflect the parameters of the design brief, the details of the concept work and the client’s expectations.

Design

click to view

Factory Liaison

click to view

Prototype

click to view

Design

Confidentiality

All of our projects start with a confidentiality contract. We take our confidentiality very seriously, and honor our contracts to the letter.

Documentation

Our documentation begins with the first conversation. We document all interactions with our clients, and provide you with a copy of our paper trail upon completion of the project.

Communication

We are excellent communicators. We produce “outcomes” documents, which communicate the information from each meeting, or presentation. This ensures that we are always on the same page as our client, and facilitates open dialog and a great working relationship in every project.

Research

Our market research gives you a snapshot of the current product landscape, identifies opportunities, and enables us to leverage our design skills effectively in your markets.

Design Brief

The design brief becomes the guiding framework for your project. This cornerstone sets the goals, vision, ideals and tone for the project.

Brand Identity

Whether we are working within the context of an existing brand or creating an identity from scratch, design signature, visual design language and brand identity are of utmost importance.

Initial Conceptualization

We form our initial conceptualization with the outcomes of our market research, the design brief, and frame it within the context of your brand and design language. During the concept phase, we throw a bunch of ideas at the wall, and see what sticks. The concept phase finishes with a formal presentation to our client. Click here to see an example of an initial concept presentation. This formal presentation is followed by feedback from our client, and then we draft an outcomes document outlining the path forward.

Final Concept Presentation

Once the initial concepts have been approved, we refine the work and the details begin to emerge. This is where the heavy lifting begins, and we sketch out every detail of the design. This phase ends with a formal final concept presentation of the product design. Click here to see an example of a Final Concept Presentation. Again, this is followed with feedback from the customer, and an outcomes document that outlines the path toward the prototype development phase.

Factory Liaison

Bill of Materials (BOM)

We develop the BOM for our products so there are no surprises when we get the price for the product from the factory. The BOM lists out the materials costs for the product, and an estimate for labor, overhead, and taxes. Click here for an example BOM.

Manufacturing Specification

Once the samples have thoroughly tested and approved, we draft the manufacturers spec’. This detailed document communicates all of the specifications to the manufacturer. Click here for an example Spec.

Factory Liaison

Wookey has relationships with dozens of manufacturing facilities both domestic and abroad. We match your products to the most appropriate factory and govern the counter-sample process. We provide on-site manufacturing quality control and ensure that the integrity of the product and quality of the manufacturing is maintained. Click here to see a gallery of images from factories that we work with.

Delivery

We work with your seasonal cycles and liaise with your forwarding agent at the factory, and delivery agent with your distribution centers, to guarantee timely delivery.

Prototype

Modeling

We use the drawings and the outcomes from the concept to build a scale three-dimensional model of your product. This model is then photographed, and can then be further embellished and rendered digitally.

Pattern Drafting

Patterns for your product are drafted directly from the model, ensuring proper relationship of seam elements and integrity of the design. Our patterns are drafted by hand to ensure accuracy and are digitized into professional pattern software that integrates with nesting software and our laser cutting equipment.

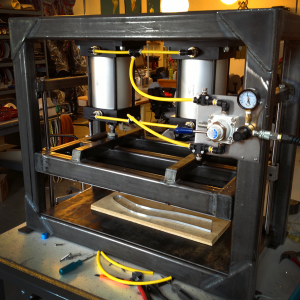

Prototyping

The sewn prototype will be nearly identical to the model and will be a fully usable product. We generally will make 1-3 revisions depending on the complexity of the product. The advantage of using our sample room capabilities is we protect your intellectual property by keeping the design out of the sample rooms in the big factories. These sample rooms tend to be “cross-pollination chambers” where ideas are shared, diluted and sometimes clearly ripped-off. Click here for a tour of our workshop.

Biometrics

Our combined 30+ years of experience with sewn product design has given us a thorough understanding of biometrics, fit, and how products need to be designed to work with the human body.

Beta Testing

We offer a range of beta testing solutions. Wookey can beta test in house, contract with professional testers, and set up test groups. Regardless of your budget and time frame, we will provide the feedback needed to bring your product closer to market.

Materials Development

Our vast knowledge base of raw materials, and our strong relationships with fabric designers, mills, and wholesalers, enables us to find or develop the perfect fabric, buckle and trim for the job, every time. We can create new and novel materials, laminated and calendared fabrics, and custom weaves. Need a new buckle? We will provide CAD drawings, prototypes, cavity creation, and production of your idea. Click here to see examples of fabrics that we have designed.

Color Palette

Our color services include: forecasting, color palette development, colorway design (color usage on the product), lab-dip evaluation, and colorfast specification. Our state of the art Pantone color evaluation equipment ensures that our work is accurate and consistent.

Our color services include: forecasting, color palette development, colorway design (color usage on the product), lab-dip evaluation, and colorfast specification. Our state of the art Pantone color evaluation equipment ensures that our work is accurate and consistent.

Graphic Design

We are expert illustrators and can provide graphic design, illustration, logo art and custom embroidery. We can also help you design catalogs, hang tags, and websites that extol the virtues of your product to your market niche.

Your brand is unique; that is why you are able to prosper in a global market. We design within the context of your brand, design signature and corporate identity. We develop designs to a high degree of clarity, eliminating the need for manufacturing partners to translate the details of samples, patterns, specifications and BOM. This process ensures that our factory time is spent addressing small details, saving you time and money.

Our passion for the outdoors enables us to create lasting designs that impact the industry. Our experience and understanding of the market is evident in every product we have designed. We look forward to working with you to create our next award-winning product!